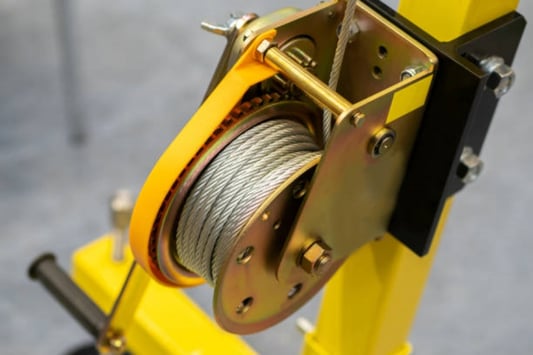

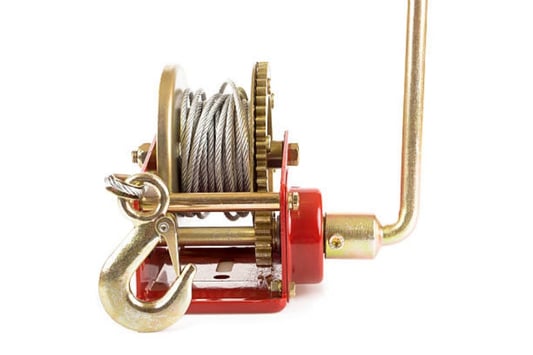

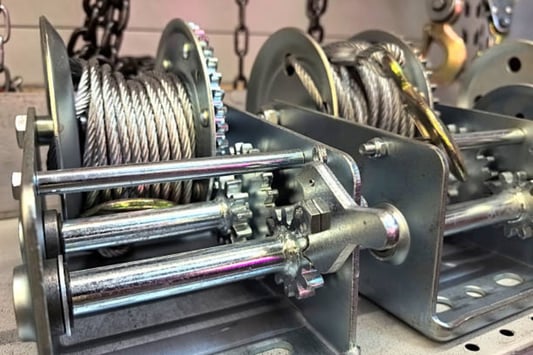

Understanding the Basics of BHW Manual Winch OperationThe BHW manual winch is a mechanical device designed primarily for lifting, pulling, or securing loads with human power. Understanding the fundamental principles of BHW manual winch operation is crucial for effective and safe use. This winch typically consists of a drum, handle, gears, and a brake mechanism, enabling controlled loading and unloading. Mastering these basics ensures users maximize efficiency during tasks such as vehicle recovery, material handling, or small construction projects.Key Components and Their Functions in BHW Manual Winch OperationEach component in a BHW manual winch plays a specific role in its overall operation. The drum holds the cable or rope, the handle provides the manual leverage, and the gear system amplifies force. The brake mechanism is vital for controlling the load and preventing slippage. Familiarity with these parts allows users to troubleshoot problems, perform maintenance, and operate the winch safely and effectively during manual winch operation.Safety Protocols Essential for BHW Manual Winch OperationOperating a BHW manual winch demands strict adherence to safety protocols to prevent accidents and equipment damage. This entails inspecting cables and gear mechanisms before use, wearing protective gloves, and ensuring the winch is mounted on stable surfaces. Additionally, never exceeding the rated load capacity and maintaining clear communication during winching operations reduces risk. Proper safety measures should be a priority in every BHW manual winch operation scenario.Step-by-Step Guide to Proper BHW Manual Winch OperationTo operate the BHW manual winch efficiently, start by securely fastening the winch to a stable anchor point. Then, attach the cable hook to the load. Begin turning the handle in a smooth, controlled manner to wind the cable onto the drum, lifting or pulling the object. Continuous monitoring prevents cable slack and ensures the load moves steadily. Releasing the brake carefully after completing the pull is key to maintaining control post-operation.Common Applications of BHW Manual Winch Operation in Various IndustriesBHW manual winch operation is widely utilized across industries such as automotive recovery, agriculture, construction, and marine sectors. Its portability and mechanical simplicity make it ideal for tasks like vehicle towing, lifting materials onto scaffolds, or adjusting boat positions. Understanding the specific demands of each sector helps tailor winch operation techniques, ensuring optimal performance and task completion.Maintenance Tips to Enhance Longevity in BHW Manual Winch OperationRegular maintenance is vital for sustaining the reliability and performance of a BHW manual winch. Key tasks include lubricating moving parts, inspecting cables for frays or damage, and tightening bolts or screws periodically. Cleaning dirt and debris from gears and handles prevents wear and tear. Proactive maintenance routines significantly improve the efficiency and safety of every BHW manual winch operation over time.Common Troubleshooting Issues During BHW Manual Winch OperationUsers may encounter problems such as cable slippage, gear jamming, or handle stiffness during BHW manual winch operation. Diagnosing the cause involves checking for worn-out cables, insufficient lubrication in gears, or damaged brake components. Addressing these issues promptly improves operational efficiency and prevents more serious mechanical failures, ensuring that the winch remains a dependable tool.Ergonomic Considerations in BHW Manual Winch OperationGiven its manual nature, ergonomics play a significant role in BHW manual winch operation. Proper body positioning, consistent rhythm during handle turning, and use of suitable grip can reduce operator fatigue and the risk of musculoskeletal injuries. Incorporating ergonomic principles enhances productivity and safety, making it easier to handle heavier loads with less strain during extended usage.Comparing BHW Manual Winch Operation with Powered Winching SystemsWhile powered winches offer automation and speed, BHW manual winch operation remains favored for its simplicity, portability, and lower cost. Manual winches do not rely on battery or electrical sources, making them indispensable in remote locations. Understanding when to use a manual winch versus a powered system depends on factors such as load weight, terrain, and operational environment.Advancements and Innovations in BHW Manual Winch OperationRecent advancements in BHW manual winch operation include improvements in materials, such as corrosion-resistant metals and synthetic cables, which enhance durability and usability. Modern ergonomically designed handles and improved braking systems contribute to user comfort and operational safety. These innovations continue to make BHW manual winch operation more efficient, extending their relevance in modern industrial and recreational applications.Quote Inquirycontact us