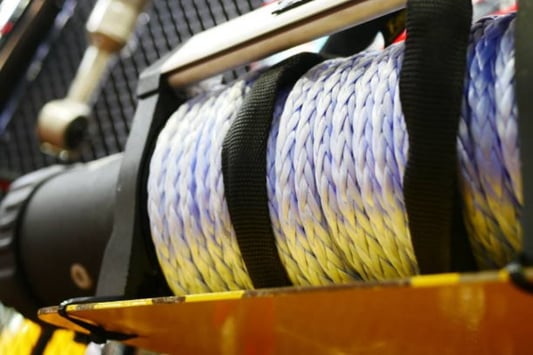

IntroductionWire rope hoists are an essential component of many industries. They are used for lifting and moving heavy loads, and are commonly found in construction sites and manufacturing plants. A wire rope hoist consists of several parts that work together to ensure its smooth operation. In this article, we will discuss the different parts of a wire rope hoist and their functions.Wire ropeThe wire rope is the main component of a wire rope hoist. It is made up of multiple strands of wire twisted together to form a strong and durable rope. The wire rope is attached to the load and the hoist, and is responsible for lifting and moving heavy objects.DrumThe drum is a cylindrical component that is used to wind and unwind the wire rope. The wire rope is wound around the drum when lifting a load and unwound when lowering the load. The drum is connected to the motor, which powers the movement of the wire rope.MotorThe motor is the power source that drives the wire rope hoist. It provides the necessary energy to lift and move heavy loads. There are different types of motors used in wire rope hoists, including electric motors and hydraulic motors.GearboxThe gearbox is a mechanical component that is used to increase the torque output of the motor. It helps to increase the lifting capacity of the wire rope hoist and enables it to lift heavier loads.Braking systemThe braking system is an important safety feature of a wire rope hoist. It is responsible for stopping the load in case of an emergency or power failure. The braking system can be mechanical or electrical, depending on the type of wire rope hoist.Control systemThe control system is used to operate the wire rope hoist. It allows the operator to control the movement of the load and the speed of the hoist. The control system can be manual or automatic, depending on the type of wire rope hoist.HookThe hook is an essential component of a wire rope hoist. It is attached to the wire rope and is responsible for lifting the load. The hook is designed to be sturdy and durable, and is capable of lifting heavy objects safely.SheaveThe sheave is a pulley-like component that is used to guide the wire rope. It is located at the top of the hoist and helps to keep the wire rope in position. The sheave can be fixed or swiveling, depending on the type of wire rope hoist.LimitswitchThe limitswitch is a safety feature embedded in wire rope hoists. It sets the limit position of the wire rope while hoisting. It is instrumental in preventing overloading, which could result in accidents and damage to machines and equipment.ConclusionIn conclusion, a wire rope hoist is a complex machine that requires several components to work together smoothly. Understanding the different parts of a wire rope hoist and their functions can help you operate and maintain the machine effectively, ensure safety, and minimize damage to the equipment.Quote InquiryContact us!