The Basics of Wire Rope in Crane Operations

Wire rope is an indispensable component of cranes, making it capable of lifting heavy loads. In this article, we’ll explore what wire rope is, how it works, and its different types.

1. Wire rope: What does it consist of?

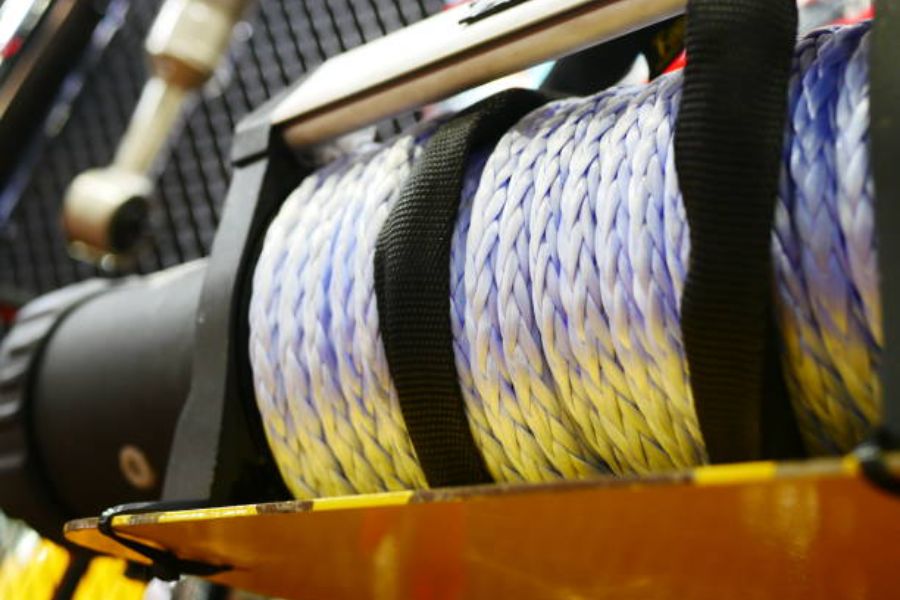

Wire ropes are made up of several strands of metal wires woven around a central core. This central core can be made of natural fibers, such as hemp, or synthetic fibers, including nylon and polypropylene. The wire ropes’ strands are typically made of steel or stainless steel, which offers strength and durability.

2. The Function of Wire Rope in Cranes

The primary function of wire rope in crane systems is to allow the transfer of heavy loads between two points. The wire rope is the primary mechanism through which loads are lifted vertically and transferred horizontally. Moreover, the strength of wire rope enables cranes to lift weights much more massive than they can handle with chains or synthetic rope.

3. Different Types of Wire Rope

There are several types of wire ropes, but the most common ones are galvanized and un-galvanized ropes. Galvanized ropes offer more resistance to rust, corrosion, and moisture damage while providing an attractive shiny appearance. Still, they are more expensive than un-galvanized ropes.

4. How Wire Rope Size Matters in Crane Operations

The diameter of the wire rope, which is referred to as the rope’s size, is critical in crane operations. A larger wire rope size has a higher safe working load, allowing for more weight to be lifted safely. Keeping in mind that increasing the wire rope size does increase the crane's cost.

5. Understanding Wire Rope Strengths

It is crucial for crane operators to understand wire rope strength and use ropes with sufficient strength to support loads efficiently. The strength of wire rope is assessed by its breaking strength; the manufacturer's desired breaking strength should be at least six times higher than the maximum working load limit for safe operations.

6. Lifespan of Wire Rope

Wire ropes are susceptible to wear and damage over time due to use, environmental factors, and other causes. However, they typically offer a service life of about 10 years (under normal operating conditions).

7. Factors Affecting Wire Rope Life Expectancy

Several factors can impact wire rope lifespan, including frequency and intensity of use, maintenance, environment, and load weight. Proper maintenance procedures, such as lubrication, inspection, and replacement of damaged wires, can extend the lifespan of wire ropes.

8. Wire Rope Safety and Maintenance

Wire ropes can be dangerous if not maintained correctly; they can snap or cause accidents when overloaded or weakened. To ensure safety, cranes and wire ropes should be regularly inspected and adequately maintained following industry standards.

9. When to Replace Wire Ropes in Crane Operations

Wire rope replacements must be made when they no longer meet the manufacturer's specified breaking strength or reliability standards. It's also essential to replace any ropes that show signs of wear or damage beyond safe limits, such as signs of corrosion, wear, kinks, or twists.

10. Conclusion

Wire ropes are essential components in crane operations. The strength and durability of wire ropes allow cranes to lift heavy loads safely. However, it's critical to understand rope types, sizes, and strength capabilities when working with cranes. Furthermore, it's crucial not only to ensure wire rope safety but also to maintain and examine the ropes regularly to maximize their operational lifespan.