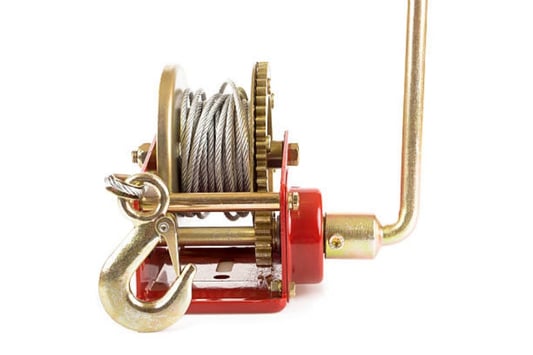

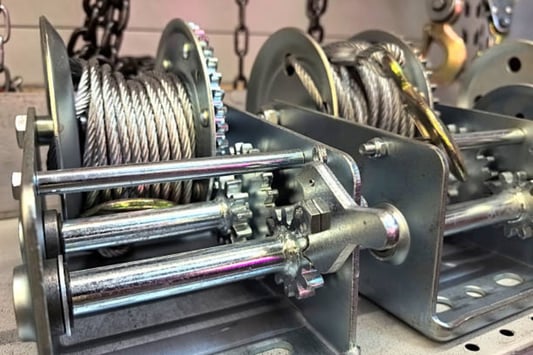

Understanding the Importance of Manual Winch Safety Manual winches are indispensable tools widely used for lifting and pulling heavy loads. However, improper handling can lead to serious accidents and equipment damage. Prioritizing Manual Winch Safety Tips is crucial to ensuring both operator safety and the longevity of the device. Awareness and adherence to safety guidelines significantly reduce risks associated with manual winch use. Inspection Before Use: The First Line of Defense A thorough inspection of the manual winch before each use is vital. Check for signs of wear, frayed cables, broken hooks, or any mechanical damage. Identifying defects early prevents malfunctions during operation. Lubricate moving parts as necessary, and always ensure the winch is firmly secured to its anchor point to avoid slippage or detachment during operation. Proper Loading Techniques to Avoid Overstrain Overloading a manual winch beyond its rated capacity is a leading cause of equipment failure. Always verify the maximum load limit specified by the manufacturer and never exceed it. Distribute weight evenly and use appropriate attachments such as shackles and slings to minimize stress on the winch components. This approach prevents cable snapping and mechanical breakdown. Securing the Load Correctly The way loads are attached to the manual winch impacts overall safety. Use secure, reliable hitch points on the load, and ensure cables or straps are properly tensioned and free from twists or knots. Incorrect load securing can cause sudden shifts or dropping, endangering both the operator and bystanders. Safe Operational Practices During Winching Operate the winch at a controlled pace, avoiding sudden jerks or rapid movements which could cause cable snapback. Maintain clear communication with anyone involved in the task, and never stand directly in line with the winch cable under tension. Utilizing gloves offers protection from cable burrs and enhances grip during handling. Using Protective Gear to Enhance Safety Wearing personal protective equipment (PPE) such as gloves, safety glasses, and sturdy boots can significantly reduce injury risk. Gloves protect hands from rope burns and cuts, while eye protection guards against debris or broken cable strands. Proper footwear ensures steady footing, especially in unstable or uneven work environments. Maintaining a Safe Distance: Keeping People Out of Harm’s Way Always keep bystanders and unnecessary personnel away from the winching area. The potential for cable failure or load displacement necessitates establishing safety zones. Use barriers, warning signs, or designated spotters to maintain a safe perimeter, minimizing the chance of accidental injuries. Emergency Procedures and Stop Mechanisms Understanding emergency protocols is an often-overlooked component of manual winch safety. Familiarize yourself with the winch’s braking system and emergency stop functions. In the event of sudden malfunctions or unexpected load shifts, being able to quickly disengage the winch can prevent accidents and equipment damage. Regular Maintenance for Longevity and Safety Scheduled maintenance is essential to manual winch safety. Clean and lubricate moving parts regularly, inspect cables for rust or corrosion, and replace worn components promptly. Proper upkeep not only extends the winch’s lifespan but also ensures the safety mechanisms function correctly when needed. Training and Adherence to Safety Standards Comprehensive training in manual winch operation, emphasizing safety tips and procedures, is critical for safe handling. Operators should be well-versed in load calculations, equipment limitations, and emergency responses. Adhering to industry safety standards and manufacturer guidelines prevents misuse and fosters a culture of safety at every level. Quote Inquirycontact us