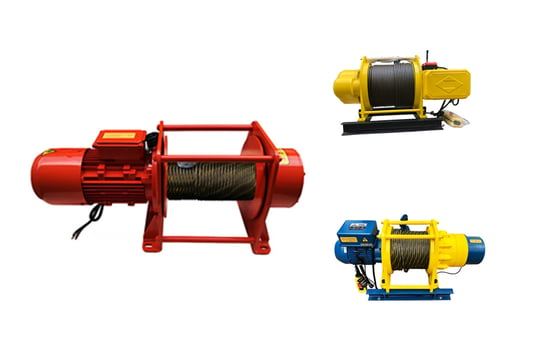

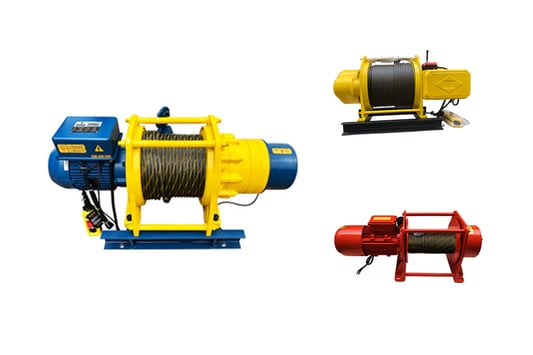

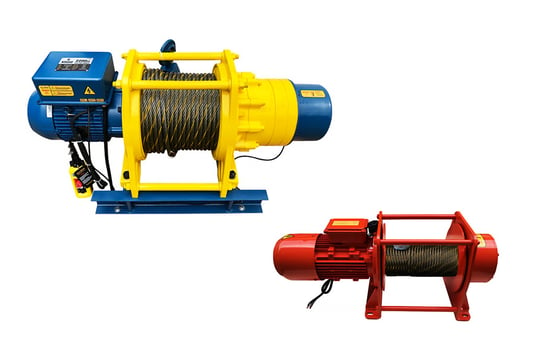

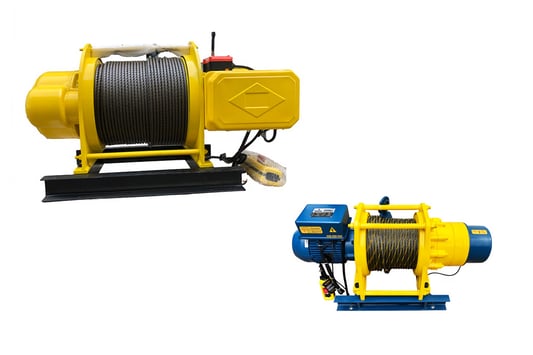

Understanding the Heavy Duty Electric Winch: An Overview A heavy duty electric winch is a powerful mechanical device designed to pull or lift heavy loads effortlessly using electrical power. These winches combine robust construction with electric motors to offer a reliable solution for applications requiring significant pulling force. They are indispensable in industries ranging from construction and automotive recovery to forestry and marine operations. Their capability to handle heavy-duty tasks with precision makes them a preferred choice over manual or hydraulic winches in many scenarios.Key Components That Make a Heavy Duty Electric Winch Effective The core components of a heavy duty electric winch include the motor, drum, gear train, and the cable or synthetic rope. The electric motor provides the necessary torque, while the gear train amplifies the pulling power. The drum stores and releases the cable smoothly, ensuring controlled movement of the load. High-quality materials such as heat-treated steel gears and durable synthetic ropes enhance longevity and performance, making these winches suitable for rigorous environments.Industrial and Commercial Applications of Heavy Duty Electric Winches Heavy duty electric winches are widely used in industries where lifting or pulling massive loads is routine. In construction, they assist in moving materials and equipment on-site. The automotive sector relies on these winches for vehicle recovery and towing operations. In maritime settings, they handle anchor handling and cargo movement. Additionally, heavy duty electric winches facilitate operations in mining, forestry, and oil and gas extraction—each requiring reliable power to boost efficiency and safety.Advantages of Heavy Duty Electric Winches Over Hydraulic and Manual Alternatives Compared to hydraulic and manual winches, heavy duty electric winches offer better ease of use, precision control, and efficiency. Electric models require less maintenance, provide faster line speeds, and deliver consistent pulling power without the need for complex hydraulic systems or strenuous manual effort. The ability to operate with remote controls and integrate with vehicle electrical systems further enhances their convenience and safety in demanding scenarios.Choosing the Right Heavy Duty Electric Winch for Your Needs Selecting the ideal heavy duty electric winch depends on various factors including the maximum load capacity, cable length, motor power, and intended application environment. Considerations such as duty cycle, line speed, and control options are equally important. Understanding the maximum load weight and operating conditions ensures the winch performs efficiently and reliably without undue wear or risk of failure.Safety Features and Best Practices When Using Heavy Duty Electric Winches Safety is paramount when operating heavy duty electric winches due to the immense forces involved. Modern winches incorporate features like automatic load-holding brakes, thermal overload protection, and emergency stop controls. Operators should always follow manufacturer guidelines, ensure proper anchoring, and avoid exceeding rated capacities. Using gloves and wearing protective gear helps prevent injuries linked to cable snapbacks or mechanical faults during operation.Maintenance Tips to Prolong the Life of Your Heavy Duty Electric Winch Regular maintenance enhances performance and durability of heavy duty electric winches. Key practices include routine inspection of cables or synthetic ropes for fraying, lubrication of gears and bearings, and checking electrical connections for corrosion. Cleaning the winch after exposure to dirt, saltwater, or extreme weather conditions prevents premature wear. Adhering to a scheduled maintenance plan safeguards against unexpected breakdowns and extends the winch’s service life.Technological Innovations Enhancing Heavy Duty Electric Winch Performance Advancements in technology have seen the integration of smart features like wireless remote controls, load sensors, and automated braking systems in heavy duty electric winches. Improved motor efficiency and lightweight composite materials reduce weight without sacrificing strength. Some models include diagnostic software that monitors performance metrics and alerts users to maintenance needs, elevating overall operational safety and productivity.Environmental Impact and Energy Efficiency of Electric Winches Heavy duty electric winches offer an environmentally friendly alternative to fuel-powered winches by running solely on electricity, often from rechargeable batteries or vehicle power sources. This reduces greenhouse gas emissions and noise pollution, making them suitable for eco-sensitive areas. Additionally, advances in electric motor design contribute to greater energy efficiency, lowering operational costs and sustaining prolonged use without significant environmental trade-offs.Future Trends in Heavy Duty Electric Winch Development Looking ahead, the future of heavy duty electric winches is promising with ongoing innovations focused on enhancing power-to-weight ratio, increasing automation, and integrating IoT technologies. This will enable real-time monitoring, predictive maintenance, and remote operation. Battery technology improvements may allow longer run times and faster recharge. Together, these trends will shape safer, smarter, and more versatile heavy duty electric winches for a broad range of industrial applications.Quote Inquirycontact us