Overview of Trolley Wheel Flange Design

trolley wheel flange design standards are crucial for ensuring the safety and efficiency of trolleys in various industries. The design of the flange plays a significant role in the overall functionality and durability of the trolley wheels. It is essential to adhere to established standards to minimize the risk of accidents and equipment failure.

Factors to Consider in Flange Design

When designing trolley wheel flanges, several factors must be taken into consideration. These include the load capacity of the trolley, the type of track it will be running on, the speed of operation, and environmental conditions. By considering these factors, engineers can design flanges that are well-suited to the specific requirements of the trolley.

Impact on Trolley Performance

The design of trolley wheel flanges can have a significant impact on the overall performance of the trolley. Flanges that are improperly designed can lead to increased wear and tear, decreased efficiency, and even safety hazards. By following established design standards, trolley manufacturers can optimize the performance of their products.

Regulatory Compliance

There are strict regulatory standards in place governing the design of trolley wheel flanges. These standards are in place to ensure the safety of workers and prevent accidents in industrial settings. Manufacturers must adhere to these standards to comply with regulations and avoid costly penalties.

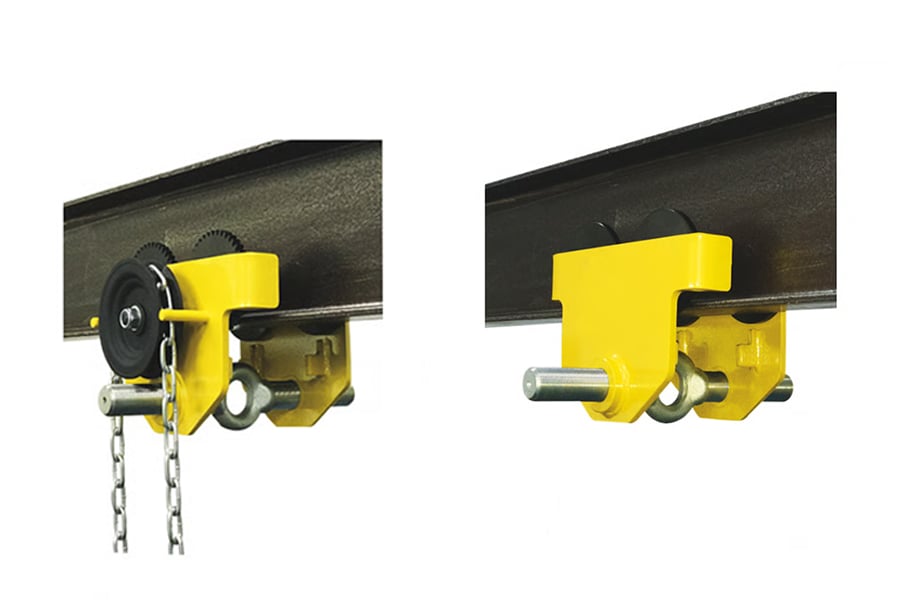

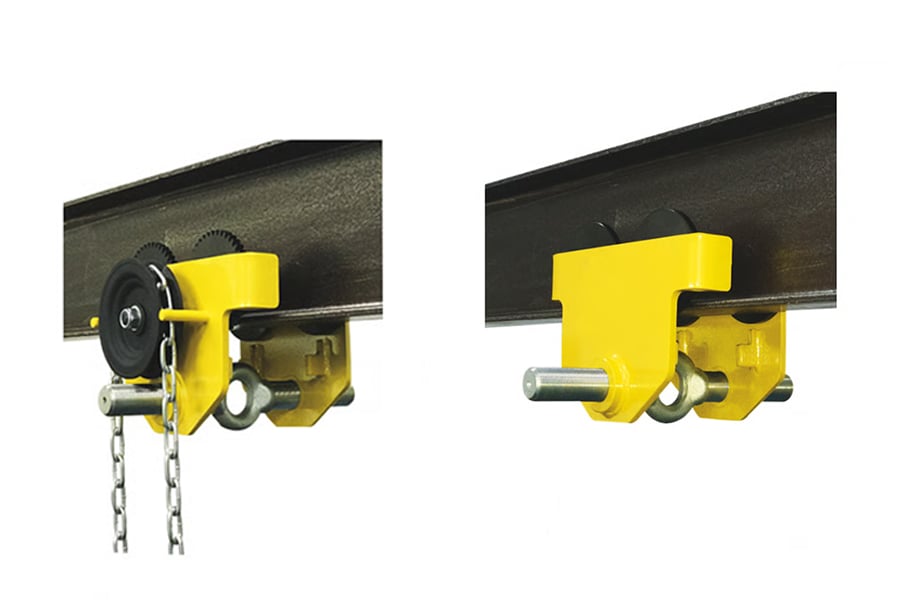

Types of Flange Designs

There are various types of trolley wheel flange designs available, each with its unique characteristics and advantages. Common designs include curved flanges, flat flanges, and tapered flanges. The choice of flange design will depend on the specific requirements of the trolley and the type of track it will be running on.

Material Selection

The materials used in the construction of trolley wheel flanges also play a crucial role in their performance and durability. Common materials include steel, aluminum, and polymers. The selection of the appropriate material is essential to ensure the longevity and reliability of the trolley wheels.

Testing and Certification

Before trolley wheel flanges can be used in industrial applications, they must undergo rigorous testing to ensure they meet industry standards. Certification from regulatory bodies is also required to validate the quality and safety of the flanges. Manufacturers must invest in testing and certification processes to ensure their products are fit for use.

Maintenance and Inspection

Proper maintenance and regular inspection of trolley wheel flanges are essential to ensure their continued performance and safety. Regular greasing, alignment checks, and visual inspections can help detect any issues early on and prevent costly damage or accidents. Following a maintenance schedule is crucial for maximizing the lifespan of trolley wheels.

Continuous Improvement

Innovation and continuous improvement play a vital role in the design of trolley wheel flanges. As technology advances and new materials become available, manufacturers must continuously update their designs to optimize performance and safety. Staying on top of industry trends and advancements is key to remaining competitive in the market.

Conclusion

Overall, trolley wheel flange design standards are a critical aspect of trolley design and manufacturing. By adhering to established standards, manufacturers can ensure the safety, efficiency, and longevity of their trolley wheels. Investing in quality design, materials, testing, and maintenance is essential for delivering reliable products that meet regulatory requirements and customer expectations.

Quote Inquiry

contact us