Understanding the Importance of Proper Manual Winch Installation

Proper

Manual Winch Installation Steps are critical to ensure safe and effective operation. A well-installed winch can prevent accidents, reduce wear and tear, and enhance performance. Neglecting correct installation can lead to mechanical failure or personal injury. This guide outlines fundamental steps to help users install manual winches correctly and securely.

Selecting the Right Location for Manual Winch Installation

Choosing the ideal mounting location is the first essential step in manual winch installation. The site must be flat, sturdy, and capable of withstanding the load forces generated during winching. Popular locations include boat trailers, trucks, and utility carts. Proper positioning helps maximize leverage and ease of use, which is crucial for manual operation.

Gathering Necessary Tools and Materials Before Installation

Before beginning manual winch installation steps, assembling the right tools is essential. Common tools include wrenches, sockets, drills, screwdrivers, and measuring tapes. Additionally, materials like mounting bolts, washers, and locking nuts should be on hand. Preparation simplifies the installation process and ensures all steps are completed efficiently.

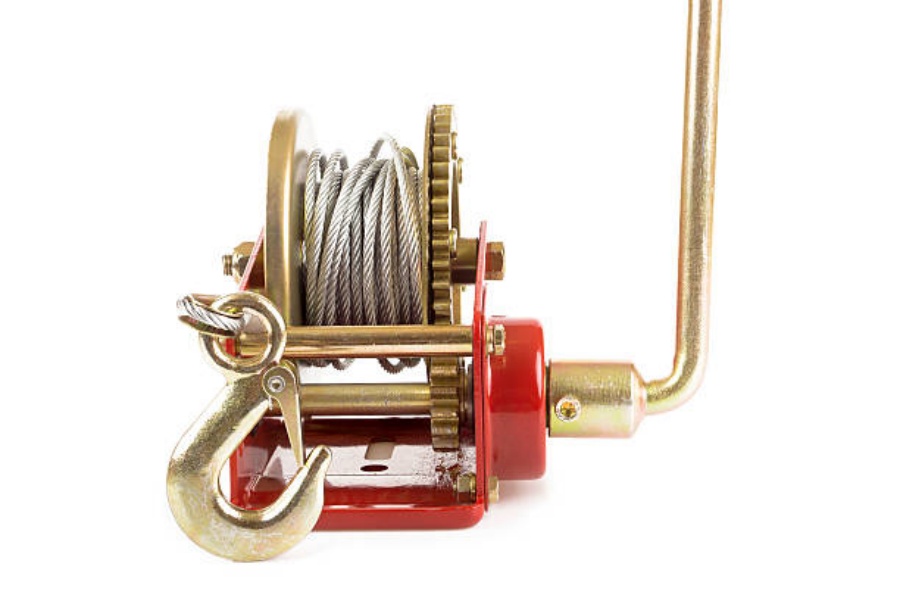

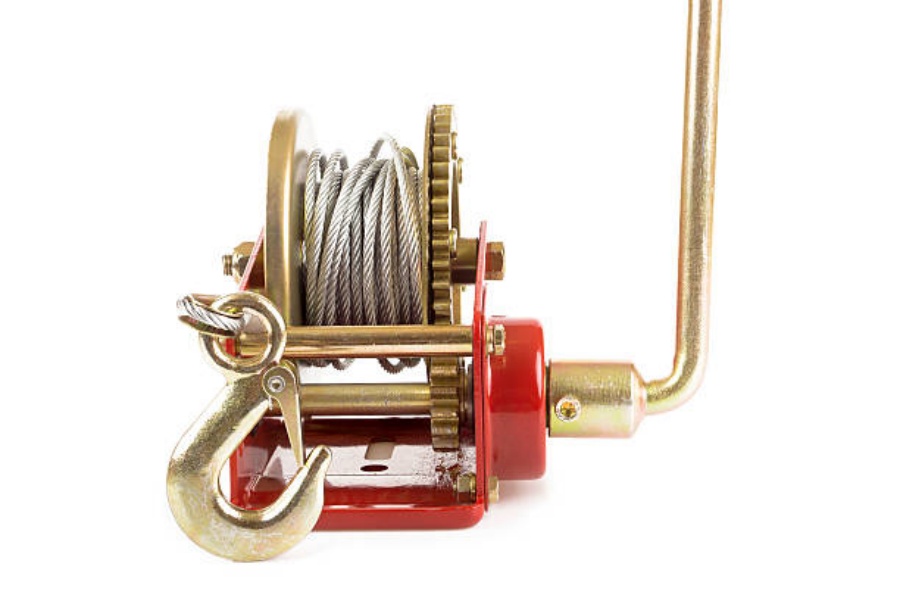

Inspecting the Manual Winch Components for Damage

Inspecting the manual winch and its components prior to installation is a crucial safety measure. Check for any manufacturing defects, rust, or damage to the cable, drum, handle, and mounting plate. Installing a compromised winch can reduce effectiveness and pose safety risks during operation.

Marking and Drilling Mounting Holes Accurately

One pivotal step in manual winch installation is marking drilling points to fit the mounting holes precisely. This requires careful measurement and alignment with the manual winch’s base plate. Using a template or the winch itself as a guide helps avoid misalignment, ensuring that bolts fit securely and the winch operates smoothly.

Securing the Manual Winch with Appropriate Hardware

Using the correct bolts, nuts, and washers is essential in securing the manual winch firmly to the mounting surface. Hardware should match the winch manufacturer’s recommendations to handle the anticipated forces. Over-tightening or under-tightening can deteriorate mounting strength, so torque specifications should be followed carefully.

Attaching the Winch Cable or Strap Safely

Proper attachment of the winch cable or strap is a fundamental step in manual winch installation. Ensure the cable is wound correctly around the drum, with no twists or overlaps that could cause jamming. Secure the cable’s hook or fastening device properly to the load or anchor point, minimizing the risk of slippage.

Testing Winch Operation Before Full Use

Testing the installed manual winch ensures functionality and safety. Operate the winch handle to check smoothness and engagement of the ratchet mechanism. Confirm the cable retracts and releases without resistance, and listen for unusual sounds indicating mechanical issues. Addressing problems during testing prevents failures in real scenarios.

Performing Routine Maintenance Post-Installation

Following manual winch installation steps, regular maintenance is vital to prolong winch life and maintain performance. Lubricate moving parts, inspect the cable for fraying, and tighten mounting bolts routinely. Maintenance checks reduce the likelihood of unexpected failures when the winch is needed most.

Safety Precautions and Best Practices During Installation

Adhering to safety precautions during manual winch installation prevents injuries and ensures effective use. Wear protective gloves and eyewear, avoid loose clothing near moving parts, and work in well-lit areas. Understanding load limits and never exceeding the winch’s rated capacity are also key to safe operation.

Quote Inquiry

contact us