What are Electric Chain Hoist Safety Standards?

Electric chain hoists are an essential tool in various industries for lifting and moving heavy loads. To ensure safe operation, there are specific safety standards set in place that must be followed. These safety standards are designed to prevent accidents and injuries in the workplace and protect the operator and surrounding personnel.

Why is Compliance Important?

Compliance with electric chain hoist safety standards is crucial to maintaining a safe work environment. By following these standards, companies can reduce the risk of accidents, injuries, and even fatalities. Non-compliance can result in hefty fines, legal issues, and a tarnished reputation for the company.

OSHA Regulations for Electric Chain Hoists

The Occupational Safety and Health Administration (OSHA) has established regulations that govern the use of electric chain hoists in the workplace. These regulations cover various aspects such as inspection, testing, maintenance, and training requirements. It is important for employers to be aware of and comply with these regulations to ensure a safe working environment.

Inspecting Your Electric Chain Hoist

Regular inspection of electric chain hoists is essential to ensure they are in proper working condition. Inspections should be conducted before each use to identify any potential issues that could compromise safety. Common things to check during inspections include the condition of the chain, hooks, controls, and overall structural integrity of the hoist.

Proper Training for Operators

Proper training is key to ensuring the safe operation of electric chain hoists. Operators should be trained on how to use the hoist correctly, as well as how to identify and respond to potential hazards. Training should be ongoing and updated regularly to keep operators informed of any changes in safety standards or regulations.

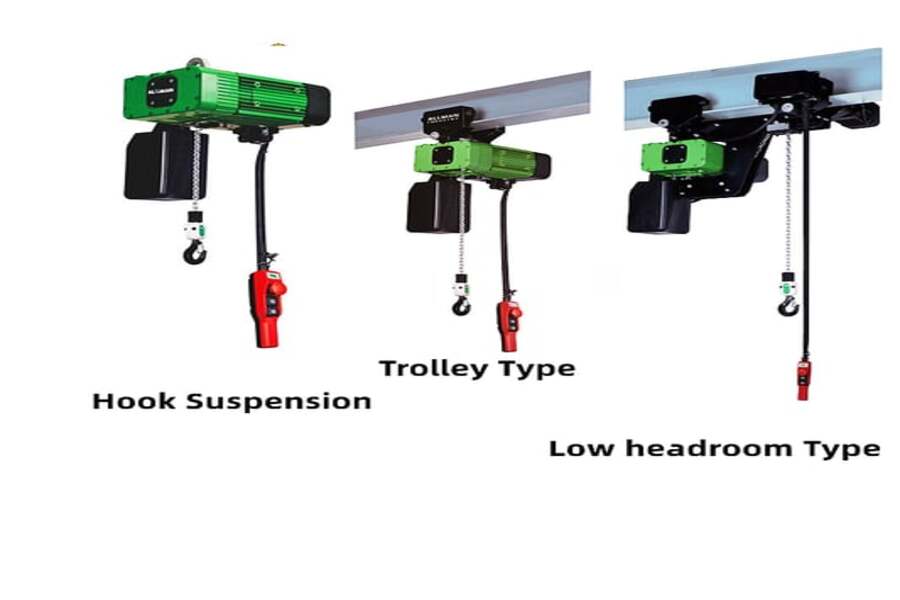

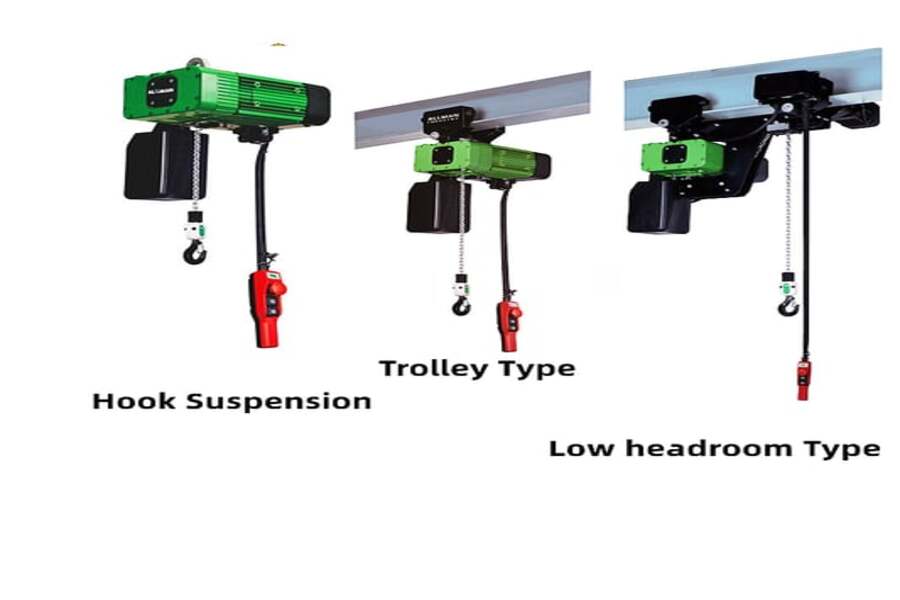

Choosing the Right Electric Chain Hoist

When selecting an electric chain hoist for your workplace, it is important to consider factors such as load capacity, lift height, and duty cycle. It is also crucial to ensure that the hoist meets safety standards and is compliant with regulations. Investing in a high-quality hoist that meets your specific needs will help ensure safe and efficient operations.

Maintaining Your Electric Chain Hoist

Regular maintenance is key to extending the life of your electric chain hoist and ensuring safe operation. Maintenance tasks may include lubrication, replacement of worn-out parts, and periodic load testing. Following the manufacturer's maintenance guidelines and schedule is essential to prevent accidents and keep the hoist in optimal condition.

Common Safety Hazards to Avoid

There are several common safety hazards associated with electric chain hoists that operators should be aware of. These include overloading the hoist, improper rigging techniques, ignoring warning signs, and lack of proper training. By identifying and addressing these hazards, companies can minimize the risk of accidents and injuries.

Emergency Procedures and Protocols

In the event of an emergency or malfunction with an electric chain hoist, it is essential to have proper procedures and protocols in place. This may include a designated emergency stop button, evacuation plans, and protocols for reporting incidents. Ensuring that all personnel are aware of these procedures can help prevent further damage or injuries.

Staying Up-to-Date with Safety Standards

Safety standards and regulations surrounding electric chain hoists are constantly evolving. It is important for companies to stay informed and up-to-date with any changes to ensure compliance. This may involve attending training seminars, consulting with safety experts, or regularly reviewing OSHA guidelines to ensure that your workplace is in compliance.

Quote Inquiry

Contact us