BHW Winch Load Handling represents a critical component in modern material lifting and transportation industries. Designed to provide controlled, reliable movement of heavy loads, BHW winches offer robust performance in diverse industrial applications. Their ability to handle significant weight with precision makes them invaluable in sectors such as construction, shipping, and manufacturing.

Key Features of BHW Winch Load Handling Systems

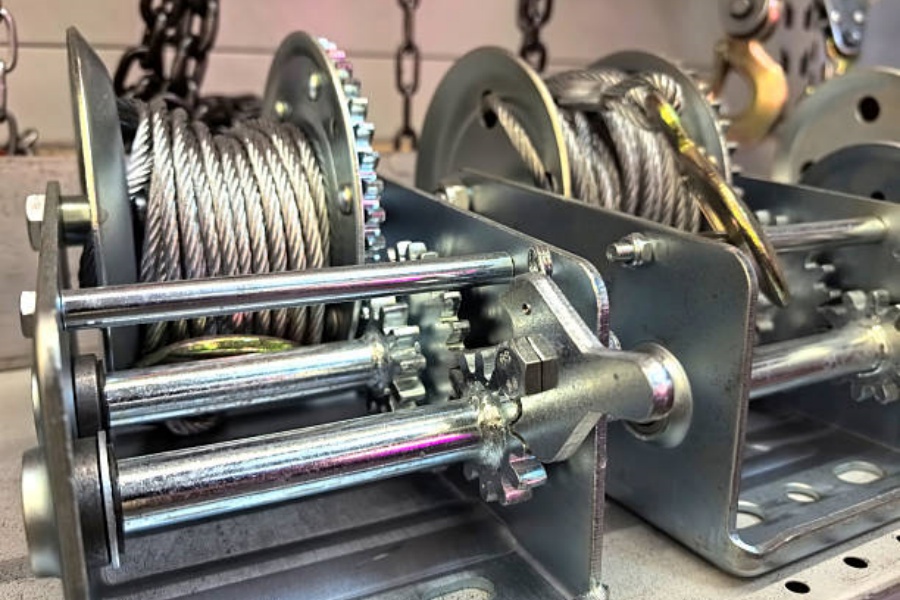

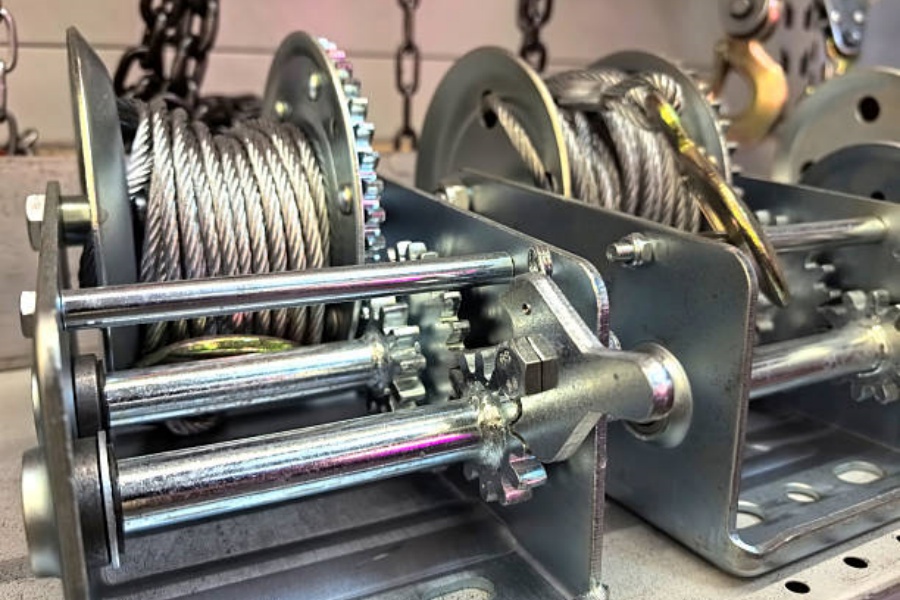

BHW Winch Load Handling systems are characterized by high load capacity, efficient braking mechanisms, and durable construction materials. These winches often incorporate steel cables or synthetic ropes optimized for heavy-duty use. Features such as adjustable speed control and automatic load-sensing technology enable operators to manage complex lifting tasks safely and efficiently.

Applications Across Various Industries

The versatility of BHW Winch Load Handling solutions allows their use in a multitude of industries. From offshore oil platforms and mining operations to construction sites and warehouses, these winches handle tasks ranging from lifting heavy equipment to pulling cargo. Their adaptability to challenging environments underscores their industrial significance.

Safety Considerations in BHW Winch Load Handling

Safety is paramount when working with heavy loads. BHW Winch Load Handling systems are equipped with multiple safety features including overload protection, emergency stop functions, and fail-safe braking to prevent accidents. Proper training and adherence to operational guidelines further enhance safe usage of these winching tools.

Technological Innovations in BHW Winch Load Handling

Recent advancements have introduced smart controls and remote operation capabilities to BHW Winch Load Handling. Integration with IoT devices allows real-time monitoring of load weight, cable tension, and winch status, providing actionable data to prevent equipment failure and improve operational efficiency.

Maintenance Requirements and Longevity

Regular maintenance is essential for optimal performance of BHW Winch Load Handling systems. Lubrication of moving parts, inspection of cables for wear and tear, and prompt replacement of damaged components ensure longevity. Scheduled maintenance programs extend the functional lifespan and reliability of the winch equipment.

Cost-Benefit Analysis of Implementing BHW Winch Load Handling

Investing in BHW Winch Load Handling solutions yields both immediate and long-term benefits. While the initial cost may be significant, increased operational efficiency, reduced downtime, and enhanced worker safety ultimately lower overall expenses. These winches also minimize the need for manual labor, further reducing labor costs.

Customization and Scalability Options

BHW Winch Load Handling can be customized to meet specific operational needs. Options include varying load capacities, cable lengths, and power sources such as electric, hydraulic, or pneumatic systems. Scalability ensures these winches can evolve with the growing demands of a business or project.

Environmental Impact and Sustainability

Modern BHW Winch Load Handling technologies are increasingly designed with environmental considerations. Energy-efficient motor systems reduce power consumption, and the use of recyclable materials in winch components supports sustainability goals. Properly maintained winches also reduce the risk of environmental hazards caused by equipment failure.

Future Trends in BHW Winch Load Handling

Looking ahead, BHW Winch Load Handling is expected to benefit from enhanced automation, AI-powered diagnostics, and improved integration with broader industrial control systems. These advancements will allow for more precise load management, minimizing human error and maximizing productivity in heavy load handling operations.

Quote Inquiry

contact us